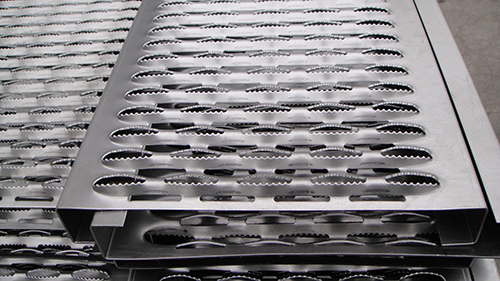

Compared with the traditional method, the laser cutting machine has the advantages of high precision, high speed, flexible processing, etc., and has obvious advantages in the processing of metal materials such as stainless steel, carbon steel and aluminum plates. Among them, stainless steel laser cutting and carbon steel laser cutting are the most widely used, which has a tendency to replace CNC punching and shearing equipment. At present, 10,000-watt laser cutting machines have been used in industrial production. With the improvement of laser cutting machine power, the efficiency of laser cutting stainless steel and carbon steel has also doubled.

Traditional sheet metal cutting equipment and process

Conventional sheet metal processing techniques are: shear-punch-bending-welding process or flame plasma cutting-bending-welding process. In the face of multiple varieties, small batches, customized, high quality, short delivery orders, it has obvious shortcomings:

● (CNC/brick tower) punching machine has restrictions on the cutting of steel plates with a thickness of 1.5mm or more, and the surface quality is not good, the cost is high, the noise is high, and it is not conducive to environmental protection;

● High-speed water cutting processing is slow, resulting in serious pollution and high cost.

New sheet metal cutting equipment and process - laser cutting

Laser cutting is a process revolution in sheet metal processing and a "machining center" in sheet metal processing. The laser cutting process has the advantages of flexibility and flexibility. In view of the problems existing in the traditional sheet metal cutting at this stage, the demand for laser cutting is also increasing.

The advantages of the new sheet metal cutting process are:

●The slit is narrow, the cutting quality is good, the degree of automation is high, the operation is simple, the labor intensity is low, and there is no pollution;

● Low production cost and good economic returns.